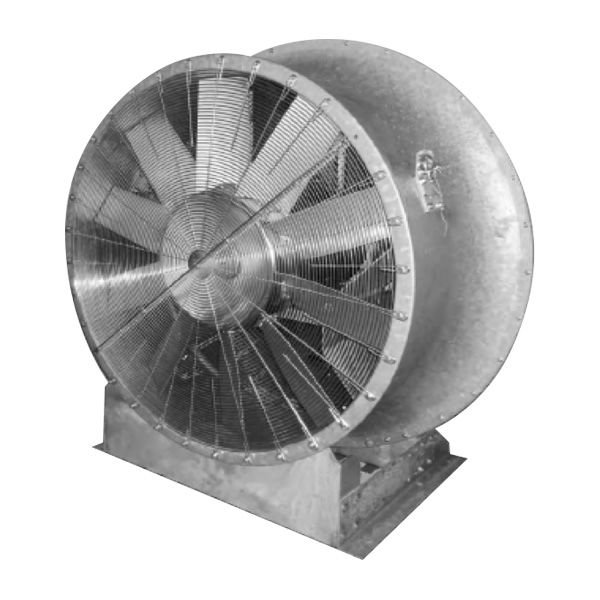

Ferrari axial fans

Series with direct drive

|

|---|

| fans at manufacturer prices |

| up to ~300,000 m³/h |

| up to ~3000 Pastat |

| adjustable blades (vanes / wings) at standstill |

| Housing also available in stainless steel or special steel |

| Air directions B (pushing over the motor) and A (sucking over the motor) |

| ATEX possible |

Areas of application

- Agriculture

- Textile

- Ceramics, bricks

- Dust collection and filters

- Safe tunnel ventilation with tunnel fans

- Energy and environmental industry

- Pharmaceuticals and chemicals

- Cement, asphalt

- Oil, gas power plants

- Food, mills

- Marine

- Painting plants

- Wood

- Tobacco

- Filter plants

- Metal industry

- Burners

- Paper, nonwovens

- Glass

- Assembly companies

The housings are made of steel or stainless and special steels and are painted, galvanised or otherwise coated.

Depending on the design, the air flow over the motor can be suction or pressure.

Conveying temperatures are standard from -20 °C to +40 °C. If required, these fans can also be designed for operation at lower and/or higher temperatures.

Operation in potentially explosive atmospheres can also be realised without any problems after prior design.

Available accessories:

Flanges, swirl controllers, butterfly valves, louvres, sleeves, suction-side filters, vibration dampers, protective grilles, inlet nozzles, mounting plates, housing feet

- Ø 315-1400 mm

- to 108,000 m³/h free-blowing

- to 1880 Pa

-

ES / EF (PDF)

-

EF series for direct request via shopping cart

-

ES series for direct request via shopping cart

-

APPLICATION

This series is particularly suitable for extracting clean air, vapours and gases - e.g. in heating systems, foundries, joineries, paper mills, chemical industry, brick and wood drying, radiator construction, cooling towers and transformers.

-

OPERATING TEMPERATURE

253 K to 313 K (-20 °C to +40 °C)

-

DESIGN

Direct drive, steel casing with deep-drawn inlet nozzle as standard and pressure-side flange to DIN 24154. Impeller made of explosion-proof die-cast aluminium with adjustable profile blades when stationary. All impellers are precisely dynamically balanced. Versions with diameter 1120 are stove enamelled. Versions with diameter 1120 and larger are supplied hot-dip galvanised as standard.

-

MOTOR

3~, 230/400 Volt, 50 Hz, type B3 (foot motor). 2, 4, 6 or 8 poles, 0,12-30 kW. Other voltages and frequencies as well as special designs on request.

-

AIR DIRECTION

Without specification is supplied as standard: via motor sucking = "A"; version via motor pushing = "B" must be specified.

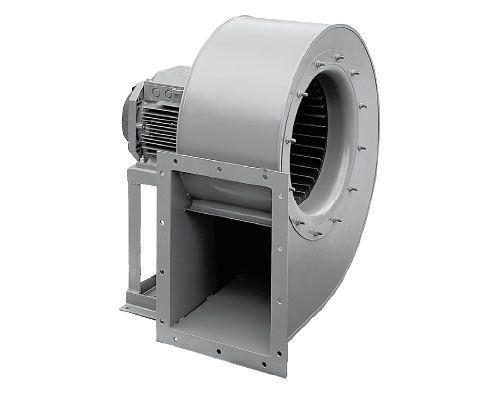

- Ø 250-800 mm

- to 48,000 m³/h free-blowing

- to 352 Pa

-

EFR (PDF)

-

APPLICATION

This series is particularly suitable for the extraction of clean air, vapours and gases (here especially for dusty or very humid air) - e.g. in heating systems, foundries, carpentry shops, paper mills, chemical industry, brick and wood drying, radiator construction, cooling towers as well as transformers.

-

OPERATING TEMPERATURE

253 K to 313 K (-20 °C to +40 °C)

-

DESIGN

Direct drive, steel casing with deep-drawn inlet nozzle as standard and pressure-side flange to DIN 24154 (on request). Impeller made of explosion-proof die-cast aluminium with adjustable profile blades when stationary. All impellers are precisely dynamically balanced. The use of a rectifier improves the technical data.

-

MOTOR

Three phases, 230/400 volts, 50 Hz, 2 or 4 poles, 0.12-30 kW, type B5 (flange motor) or B14 without bonnet and cooling vanes. Other voltages and frequencies as well as special designs on request.

-

AIR DIRECTION

Without specification is supplied as standard: Pressing via motor = "B"; Suction via motor = "A" must be specified.

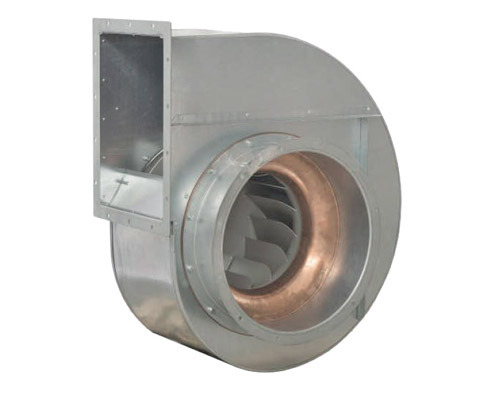

- Ø EK 315-560 mm

- Ø EQ 315-1000 mm

- Ø EP 315-630 mm

- to 34.000 m³/h free-blowing

- to 210 Pa

-

EK, EQ, EP (PDF)

-

APPLICATION

EK: These fans are particularly suitable for extracting flue gases as well as humid and dust-laden air and vapours.

EQ: These fans are suitable for the ventilation and extraction of heat, smoke and stale air.

EP: These fans are suitable for ventilation and for extracting heat, smoke and stale air.

-

OPERATING TEMPERATURE

253 K to 313 K (-20 °C to +40 °C)

-

DESIGN

Direct drive, steel casing with deep-drawn inlet nozzle as standard and pressure-side flange to DIN 24154. Impeller made of explosion-proof die-cast aluminium with adjustable profile blades when stationary. All impellers are precisely dynamically balanced. Motor support (type B5) is provided by protective grille as standard.

-

MOTOR

Three-phase, 230/400 volts, 50 Hz, type B5. Other voltages and frequencies as well as special designs on request.

-

AIR DIRECTION

Without specification is supplied as standard: Suction via motor = "A"; Push via motor = "B" must be specified.

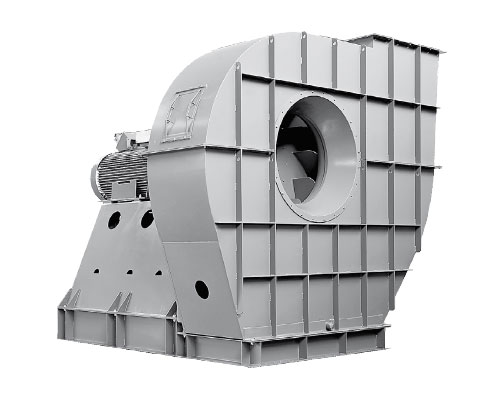

- Ø ES/H 900-1800 mm

- Ø EF/H 900-2000 mm

- to 350,000 m³/h freiblasend

- to 1100 Pa

-

ES/H, EF/H (PDF)

-

APPLICATION

ES/H: The design of these fans with a large inlet nozzle helps to minimise the noise levels in factories. This series is particularly suitable for extracting clean air, vapours and gases - e.g. in heating systems, foundries, joineries, paper mills, chemical industry, cooling towers and transformers.

EF/H: This series is particularly suitable for sewage systems, dryer systems and for extracting dusty or humid air; i.e. wherever large quantities of air are to be conveyed at low and medium pressures. Main applications: foundries, cement factories, carpentry, drying plants, chemical and paint industries.

-

OPERATING TEMPERATURE

253 K to 313 K (-20 °C to +40 °C)

-

DESIGN

ES/H: Direct drive, steel casing with deep-drawn inlet nozzle as standard as well as pressure-side counterflange according to DIN 24154. Impeller with conical hub made of grey cast iron as well as with blade profile vanes adjustable at standstill. All impellers are precisely dynamically balanced. The casings are hot-dip galvanised as standard.

EF/H: Direct drive, tubular model - steel casing with flanges on both sides to DIN 24154 and cleaning flap. Impeller with conical hub made of grey cast iron and steel bonnet as well as with impeller blades made of cast aluminium that can be adjusted at standstill. All impellers are precisely dynamically balanced. The casings are hot-dip galvanised as standard.

-

MOTOR

Three-phase, 230/400 volts, 50 Hz, 4-, 6- and 8-pole, type B3. Other voltages and frequencies as well as special designs on request.

-

AIR DIRECTION

Without specification is supplied as standard: Suction via motor = "A"; Push via motor = "B" must be specified.

- Ø 560-1600 mm

- to 265,000 m³/h free-blowing

- to 350 Pa

-

EFR.../P (PDF)

-

APPLICATION

This series is particularly suitable for the extraction of clean air, vapours and gases (especially in the case of dusty or very humid air) - e.g. in heating systems, foundries, joineries, paper factories, chemical industry, brick and wood drying, radiator construction, cooling towers and transformers. This series is particularly low-noise.

-

OPERATING TEMPERATURE

253 K to 313 K (-20 °C to +40 °C).

-

DESIGN

Direct drive, steel casing with deep-drawn inlet nozzle as standard as well as pressure-side flange according to DIN 24154 (on request). Impeller with conical hub made of grey cast iron as well as vane profile blades adjustable at standstill. All impellers are precisely dynamically balanced.

-

MOTOR

Three-phase, 230/400 volt, 50 Hz, 2-, 4-, 6-pole, type B5 or B14 without bonnet and cooling vanes. Other voltages and frequencies as well as special designs on request.

-

AIR DIRECTION

Normally the fan is supplied with air flow from the impeller to the motor.