HVLS and axial cross-flow fans from Evel

Energy-efficient Evel ventilation systems - cooling fans especially for dairy farms

BAFA and animal welfare grant of up to 40 % of the acquisition costs

HVLS ceiling fans and axial supply air fans (for cross-flow ventilation / supplying fresh air / circulating air) for- Industry

- Agriculture

- for open stable concepts (dairy cows / cattle) and exercise pens

- suitable for both cow stables / cowsheds and pigsties

- Trade

- Catering (hotels, restaurants)

- Halls

- Gyms, sports halls, ...

Evel WZ/WR/WF range

HVLS ceiling fans

TDA system (temperature difference equalisation system) to avoid thermal stratification and reduce heating costs by up to 30 % in high rooms

HVLS fans (high volume low speed) are large ceiling fans – so-called “helicopter” fans – for halls, e.g. in industry, trade, storehouses, cold stores, greenhouses and in agriculture – especially for cow stables and open stalls, which are increasingly being used in pig farming. They generate an even, vertical flow of air.

Compared to many competitor products, HVLS fans from Evel offer an incomparably high air output and throw distance thanks to their optimized blade profile, so that, for example, when equipping stables, fewer ceiling fans are needed than many competitors.

HVLS fans were originally developed to meet the requirements of dairy farming. If dairy cows are stressed by heat, they become sluggish and milk production sinks.

In the cold season, HVLS fans make a significant contribution to reducing heating costs in high spaces such as industrial halls by up to 30 %. Cold air collects in the occupied area near the floor and warm air accumulates under the hall ceiling - depending on the hall height and insulation, 30 °C and more are reached here. The HVLS fans compensate for these temperature differences by preventing the formation of heat layers.

HVLS fans provide an energy-efficient option for improving the well-being of dairy cows. As with humans, working animals that breathe in bad air develop health problems and perform less efficiently as a result. Studies have shown that, for example, the animals’ intake of food decreases less or not at all even at high temperatures and that milk production and its content remains constant. The fans achieve these effects in both exercise pens and stables.

Excessive high temperatures repeatedly lead to circulatory problems and total breakdowns in cattle. Across their lifetime, the loss per cow is well into the five-figure euro range. The downtimes for industrial machines and components are also reduced.

The use of such fans immediately leads to improvements in animals with regard to their circulatory problems. Udder diseases in cows also drop significantly: the formation of condensation on the floors and the hall ceilings is avoided and the spread of viruses, bacteria and mould is reduced.

Video Evel WZ/WF Serie

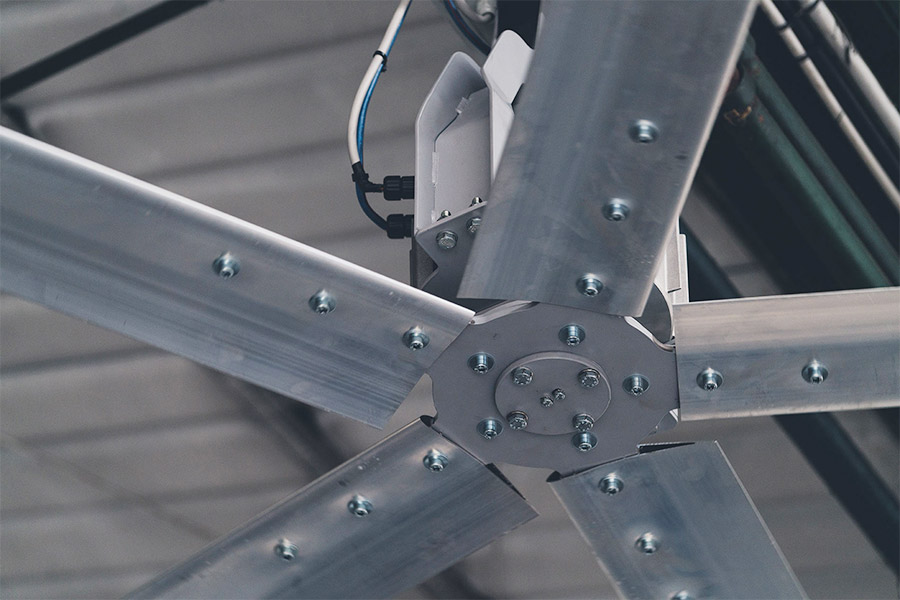

Technology

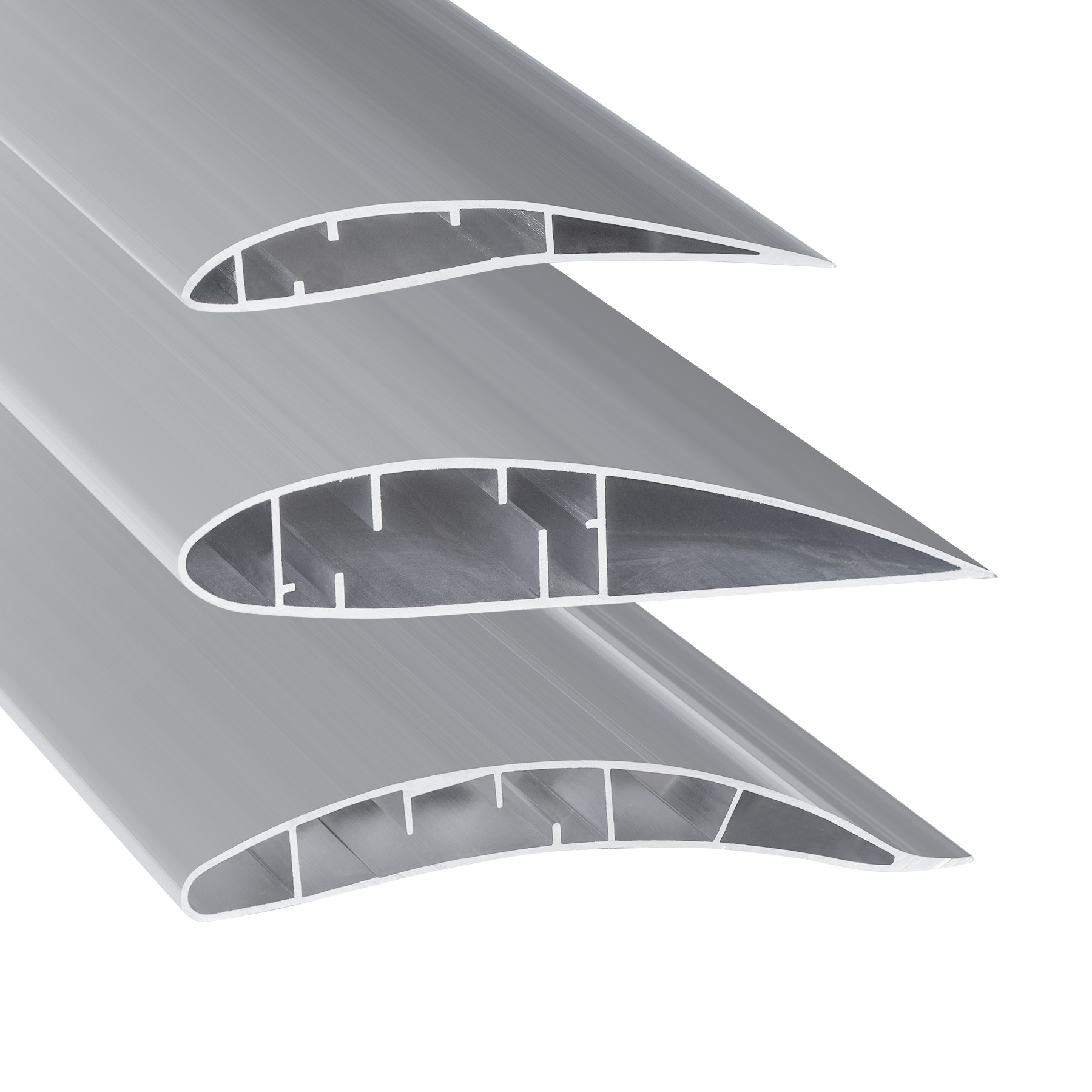

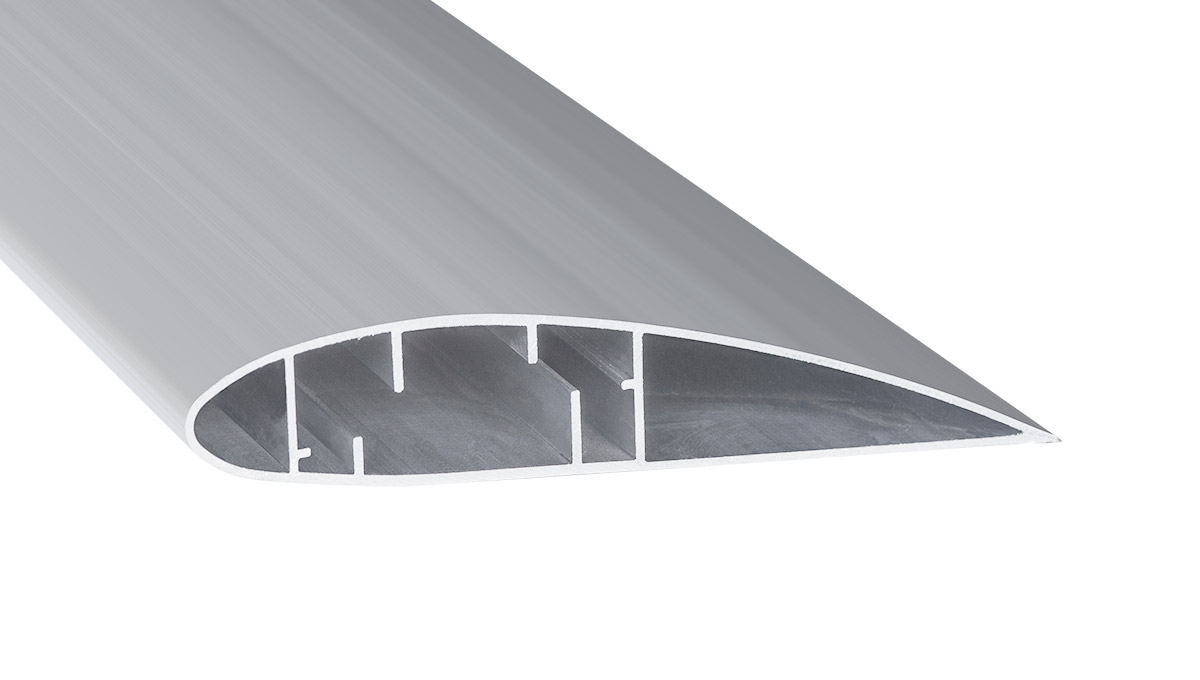

- WF range: 2.5 - 4 m for the catering industry – the air is pressed down by the blade profile

- WZ range: 2.5 - 7 m for industry and animal farming (UL certified): The air is pressed down and to the sides by the blade profiles

- Direct drive: Maintenance-free EC magnetic motors (with integrated frequency converter), brushless, with integrated inverter and thermal overload protection; energy saving of up to 40 % compared to a conventional AC motor

- Can be operated with 1~230 V or 3~400 V, AC, 50 Hz

- No fault-prone and high-maintenance gearbox required

- Protection class IP65 = suitable for all working environments

- Easy to assemble

- Problem-free, simple control by means of 0-10 V DC control signal, can also be controlled using Modbus via the building management system. Large selection of control units available for temperature, air speed, air humidity, ammonia (NH3) or air quality. Up to 16 HVLS fans can be operated simultaneously using an X9-EV control system. Other control system options include microfan control with touch screen operation or control via an app.

- Possible to run forwards and backwards

- Low power consumption at high air output of up to 850,000 m³/h: air is supplied to the animals at a speed of approx. 3 m/s

- Standardised and special blade profiles for high throw distances of up to 28 m; additionally supplemented by winglets; blades can be supplied with a smooth aluminium surface – alternatively, they can also be supplied lacquered or anodised for higher corrosion-resistance

- 5 blades

- Very quiet – e.g. <45 dB(A) for a diameter of 5 m

- Temperature range from -20 °C to +50 °C

- Fatigue resistance tested: FEM, dynamic measurements via telemetry, lab tests

- Safety: twin screws on the motor shaft, friction connection through conical motor shaft and slip guard ensure rotor cannot fall out. In addition to the vertical installation of the fan, additional protection against vibrations is provided by tensioned ropes.

- Arranging the fans directly above the animals in the stables means the food won’t dry out. Depending on the situation on-site, several small fans may be better than one large one.

- Planning support from Ventos; combination of HVLS fans with cross-flow fans from the WA range for supplying fresh air

WZ range _ Technical data for HVLS fans

(alternative: WR range with motor, inverter and gearbox)

| Ceiling fan model | Design |

Diameter [m] |

Minimum ceiling suspension distance ... Blades [m] |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Max. current consumption [A] |

Noise [dB(A)] |

Volume [m³/h] |

Throw distance [m] |

|---|---|---|---|---|---|---|---|---|---|---|

| WZ 2500 | 2.5 | 0.75 | 82.5 | 210 | 1.120 | 2.68 | < 60 | 210,000 | 7.5 | |

| WZ 3000 | 3.0 | 1.00 | 86.0 | 150 | 0.600 | 1.43 | < 60 | 310,000 | 9.0 | |

| WZ 4000 | 4.0 | 1.00 | 94.0 | 100 | 0.650 | 1.67 | < 55 | 370,000 | 15.0 | |

| WZ 5000 | 5.0 | 1.50 | 113.0 | 80 | 0.850 | 1.97 | < 45 | 530,000 | 18.0 | |

| WZ 6000 | 6.0 | 1.50 | 121.0 | 65 | 1.100 | 2.69 | < 45 | 600,000 | 20.0 | |

| WZ 6000 HP | High-speed motor | 6.0 | 1.50 | 132.0 | 75 | 0.760 | 1.89 | < 45 | 670,000 | 25.0 |

| WZ 7000 | 7.0 | 1.50 | 129.0 | 38 | 0.525 | 1.35 | < 45 | 650,000 | 28.0 | |

| WZ 7000 HP | High-speed motor | 7.0 | 1.50 | 140.0 | 50 | 0.665 | 1.65 | < 45 | 850,000 | 28.0 |

| WR 5000 | 5,0 | 0,75 | 92,7 | 75 | 0,618 | 1,9 | < 45 | 490.000 | 18,0 | |

| WR 6000 | 6,0 | 1,0 | 101,0 | 65 | 0,662 | 2,7 | < 45 | 510.000 | 20,0 | |

| WR 7000 | 7,0 | 1,0 | 109 | 45 | 0,527 | 2,8 | < 45 | 680.000 | 18,0 |

WF range _ Technical data for HVLS fans

| Ceiling fan model | Design |

Diameter [m] |

Minimum ceiling suspension distance ... Blades [m] |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Max. current consumption [A] |

Noise [dB(A)] |

Volume [m³/h] |

Throw distance [m] |

|---|---|---|---|---|---|---|---|---|---|---|

| WF 2500 | 2.5 | 0.75 | 66.5 | 150 | 1.000 | 2.50 | < 60 | 190,000 | 7.5 | |

| WF 3000 | 3.0 | 1.00 | 70.0 | 115 | 0.725 | 1.97 | < 60 | 280,000 | 9.0 | |

| WF 4000 | 4.0 | 1.00 | 76.5 | 80 | 0.370 | 1.01 | < 55 | 330,000 | 15.0 | |

| WF 4000 HP | High-speed motor | 4.0 | 1,00 | 82.0 | 95 | 0.435 | 0.93 | < 55 | 350,000 | 18.0 |

Summary

Uniform air distribution – cooling in the summer - energy saving of approx. 30 % in the winter

Summer function: In the stable, heat from the animals and the sun must be dissipated. This is achieved through increased air speed. The ceiling fan generates an even, vertical air flow under its blade. On the floor, the air flow is redirected outwards and then flows along the walls and ceiling and back to the fan. The perceived temperature can be reduced by up to 6 °C in this way. The energy requirement for this is around 600 W.

Winter function: Heat accumulated on the ceiling is sent back into the occupied area by the ceiling fans. Up to 30 % of heating costs can be saved in this way. Thanks to the interplay of ceiling and floor sensors, the temperature difference in the air layers is determined; this is then used to adjust the speed of the fan. The energy requirement for this is approx. 0.15 kW/h. The distribution of air inside the building is uniform and doesn’t create draughts: YouTube video

Installation information

The fans should only be installed by specialists and in compliance with the relevant VDE regulations and in accordance with the installation instructions of the fan in question. We recommend using protective switches sensitive to all currents.

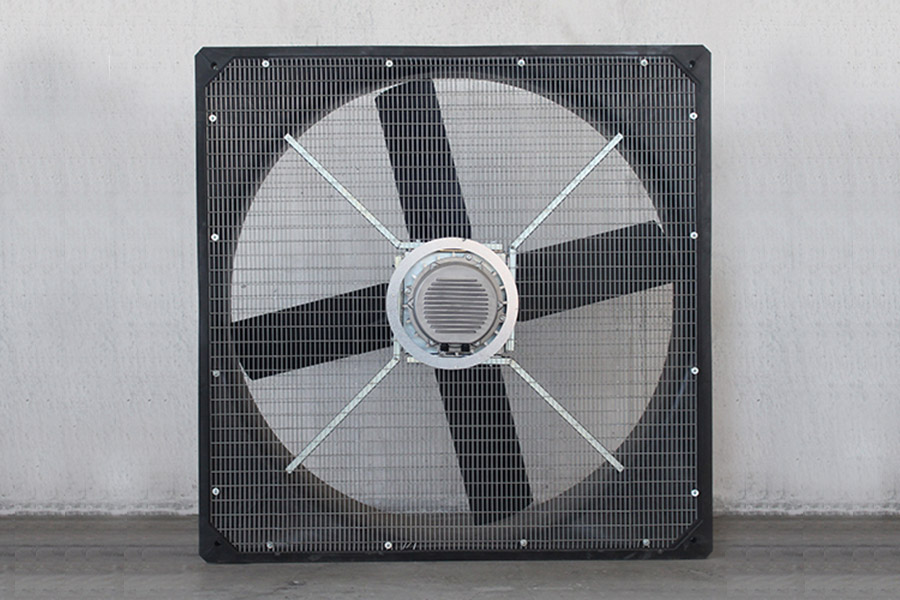

Evel CROSS Series

Fans for cross-flow ventilation / supplying fresh air / circulating fans for cows/cattle / fresh air supply to reduce heat stress in dairy cattle barns

Technology

- Combines the advantages of HVLS fans and WA fans: High air performance with low noise and at the same time high throw distance and width

- Energy-efficient EC motor with frequency converter and sine filter

- Up to 50% more economical than comparable asynchronous motors

- Protection class IP65

- Aluminium-blades with efficient Naca-profile

- Can be used for cross-flow ventilation / supplying fresh air in greenhouses or for cross-flow ventilation in cowsheds, pigsties or poultry houses, directed at the area you want the animals to occupy

The high throw and width of the Evel CROSS fans means that fewer fans are needed in the barn than with comparable systems. This often means that not only are the installation costs for a barn lower, but also the overall running costs - e.g. energy costs. This also has a positive effect on the noise level.

Video Evel CROSS Series

CROSS Series Technical data fan (cross-flow ventilation / supplying fresh air)

| Type | Design |

Diameter [m] |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Max. current consumption [A] |

Noise [dB(A)] |

Volume [m³/h] |

|---|---|---|---|---|---|---|---|---|

| CROSS 2000 | 3 wings | 2,0 | 48,0 | 260 | 0,40 | 0,90 | < 70 | 140.000 |

| CROSS 2500 | 3 wings | 2,5 | 50,4 | 255 | 0,93 | >2,03 | < 70 | 160.000 |

* Grids can be omitted from installation heights of 2.7 m and up (25 % more air output without protective grate)

Installation information

The fans should only be installed by specialists and in compliance with the relevant VDE regulations and in accordance with the installation instructions of the fan in question. We recommend using protective switches sensitive to all currents.

Evel FF range

Mobile HVLS fans

Technology

- Flower fan design

- Installation outdoors and indoors

- Protection class IP65 = suitable for all working environments

FF range _ Technical data mobile HVLS fans

| Type |

Diameter [m] |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Max. current consumption [A] |

Noise [dB(A)] |

Maximum area [m2] |

Volume [m³/h] |

|---|---|---|---|---|---|---|---|---|

| Flower Fan 3000 | 3 | 285 | 200 | 0.855 | 2.03 | < 60 | 900 | 260,000 |

| Flower Fan 4000 | 4 | 290.8 | 140 | 0.843 | 1.98 | < 60 | 1,400 | 300,000 |

Evel WA range

Fans for cross-flow ventilation / supplying fresh air / circulating fans for cows/cattle / fresh air supply to reduce heat stress in dairy cattle barns

Technology

- Energy-efficient EC motor with frequency converter and sine filter

- Up to 50% more economical than comparable asynchronous motors

- Protection class IP65

- Plastic blades

- Square wall ring plate made from plastic (stable plastic nozzle), dimensions: 1400 x 1400 mm, thickness of the wall ring plate 368 mm, 508 mm with housing

- Can be used for cross-flow ventilation / supplying fresh air in greenhouses or for cross-flow ventilation in cowsheds, pigsties or poultry houses, directed at the area you want the animals to occupy

The high throw and width of the Evel WA fans means that fewer fans are needed in the barn than with comparable systems. This often means that not only are the installation costs for a barn lower, but also the overall running costs - e.g. energy costs. This also has a positive effect on the noise level.

Video Evel WA range

WA range _ Technical data fan (cross-flow ventilation / supplying fresh air)

| Fan type | Design |

Diameter [m] |

Deep plastic nozzle [mm] (motor protrudes) |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Max. current consumption [A] |

Noise [dB(A)] |

Volume [m³/h] |

Throw distance (~2 m/s) [m] |

|---|---|---|---|---|---|---|---|---|---|---|

| WA 1400STD | with grid*, 4 wings | 1.4 | 368 | 47.0 | 330 | 0.8 | 2.42 | 82.4 | 41.000 | ~25.0 |

| WA 1400P | with shutter, 3 wings | 1.4 | 368 | 85.0 | 330 | 0.8 | >2.42 | 82.4 | 41,000 | ~25.0 |

| WA 1400ECO2 | with* / without grid, 3 wings | 1.4 | 368 | 45.0 | 750 | 0.51 | 0.83 | 81.9 | 30,000 | ~25.0 |

| WA 1400MAX | with* / without grid, 3 wings | 1.4 | 368 | 45.0 | 560 | 1.46 | 4.33 | 89.2 | 43,500 | ~25.0 |

* Grids can be omitted from installation heights of 2.7 m and up (25 % more air output without protective grate)

Installation information

The fans should only be installed by specialists and in compliance with the relevant VDE regulations and in accordance with the installation instructions of the fan in question. We recommend using protective switches sensitive to all currents.

DF range

Mobile drum fans for cross-flow ventilation / supplying fresh air

Technology

- Can be operated in 3 stages by means of pressure switch, two-pole on/off switch; optional transformer for 5 stages

- Vertical inclination can be adjusted by 360 °

- Impeller made from aluminium, aerodynamically optimised

- Protection class IP54

- Robust design

- Protective grate, housing (stable, tilt-proof with rubber rollers, handle and cable wrap – 2.5 m cable with Schuko plug), frame and impeller painted black

- Ideal for mobile use in agriculture, production, warehousing and shipping

DF range _ Technical data drum fans

| Fan type | Design |

Diameter [m] |

Overall dimensions W x H x T [mm] |

Weight [kg] |

Speed [min-1] |

Max. power consumption [kW] |

Noise [dB(A)] |

Volume [m³/h] |

|---|---|---|---|---|---|---|---|---|

| DF 600 Eco SL IP54 | mobile drum fan | 0.68 | 750 x 770 x 270 | 16.3 | 870 | 0.123 | 78.9 | 13,000 |

| DF 800 Eco SL IP54 | mobile drum fan | 0.83 | 880 x 920 x 260 | 19.3 | 870 | 0.123 | 76.1 | 15,650 |