| Materials | ||||||

|---|---|---|---|---|---|---|

| Material-No. | Designation | Further designations | Hardness HB | Temperature resistance °C | Conductivity MS/m | |

| 2.0850 | CuNi2Be / VNB-850 | CW110C, C17510, Hovadur CNB spez, Brocadur NIBE, Wirbalit NIB, Elmedur HC, Elmedur HC, Elbrodur D, Berylco 14 / B14, Legierung 3, Ampcoloy 89 | ≥220 | 480 | ~38 | |

| 2.1285 | CuCo2Be | CW104C, C17500, Hovadur CCB, Brocadur CCB, Wirbalit B, Elmedur HA, Elbrodur B, Legierung 10, Ampcoloy 88/91/95/940, CB4, Mallory 100, Klasse 3, NS | ≥210 | 480 | ~25 | |

| 2.1285 | CuCo1Ni1Be | CW103C, Hovadur CCNB, K96 | ≥210 | 480 | ~28 | |

| 2.1293 | CuCr1Zr | CW106C, C18150, Hovadur CCZ, Brocadur CCZ, Wirbalit HF/N/F, Elmedur X, Elbrodur HF/N/G, Ampcoloy 972, CRM16, Mallory 328, Klasse 2, CCS/Z | ≥150 | 500 | ~44 | |

| Special material | Cual2O3 | - | ≥150 | 900 | >45 | |

Application examples

- Resistance welding electrodes for wire grates and wire baskets.

- Electrodes for Wafios KEH, KSH and KSF and Vitari MS and SH chain welding machines.

- Welding rollers and counter electrodes for roll seam welding.

- Interchangeable electrodes for projection welding

- Tools in plastics machinery: mold inserts/cavities, slides, ejectors, core and nozzle tips, sprue channels/hot runners for injection molding, extrusion and blow molding

- EN12163 (Round bars)

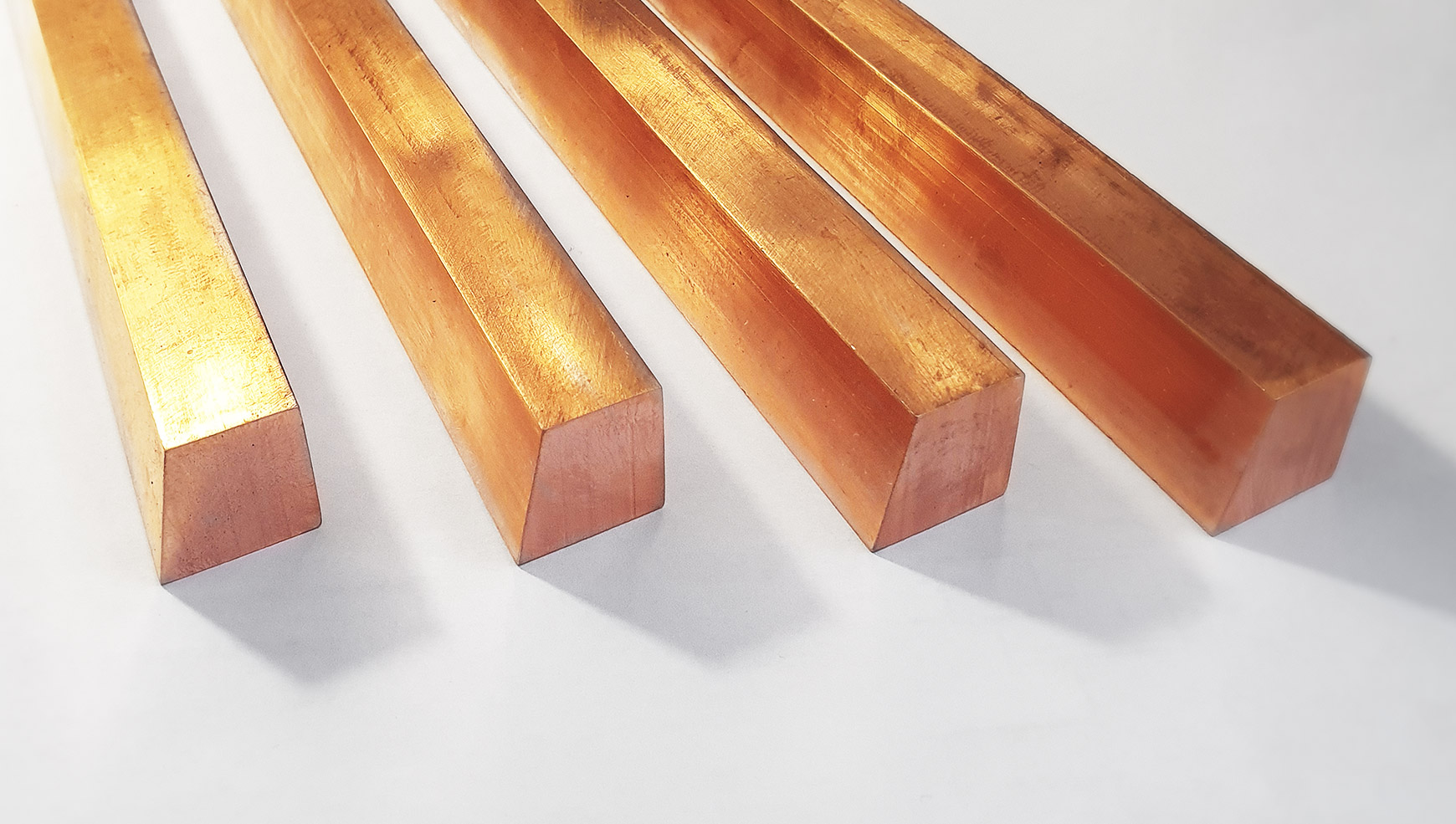

- EN12167 (Flat bars, profiles)

- EN12420 (Forge products)

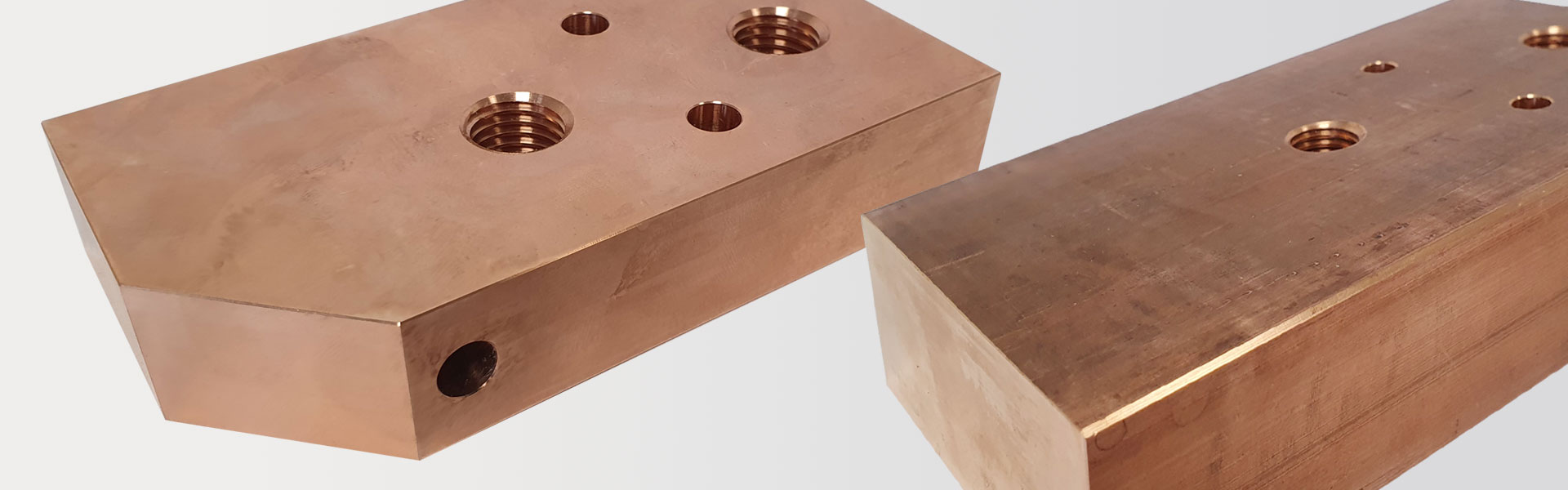

- Cut to desired size

- Cut to length with end machining

- According to drawing

Further information

Assurances regarding the existence of specific properties or the intended use always require written agreement with Ventos Lüftungstechnik GmbH.

Alloys sometimes contain Beryllium. Therefore, the creation of dust, vapours and smoke should be avoided when working with the material, e.g. when dry grinding, polishing or welding. Vapours and dust must not be inhaled. Avoid contact with skin and eyes. Milling and turning is not generally considered dangerous.